One of the biggest fears about buying product overseas, putting your name on it, and selling it to folks all over the country is that, despite all the precautions you’ve taken and steps to ensure each frame is dialed by inspecting each one before it goes out, something may go wrong. Recently, that something was a couple of water bottle bosses. It is evident that these two bosses were not brazed in properly.

This actually happened once before and because it happened on a local rider’s first ride, I attributed it to an anomaly. A one-time thing. This rider came by the shop after his ride and showed me the boss that came out and the hole in the frame. I was horrified. He was calm and cool. This was one of those moments you think to yourself, “why am I doing this? I should just be selling $400 hybrids instead of trying to do something different.”

However, once we both assessed the situation, I realized that the hole in the down tube was the same hole that was drilled for the boss in the first place and that it’s not uncommon to have to replace bottle bosses on aluminum frames with new rivet nuts. The solution of installing a rivet nut in the frame was reached and he’s been going strong since that day in January. It was a good fix. And I forgot about it. Until recently.

The e-mail showed up “Broken water bottle braze-ons” and I knew what happened and that it happened a second time. One-time incidents are just that, one-time. When it happens twice, the potential for it to happen a third time increases, but it’s not likely epidemic. I checked the frame that happened to be in the stand getting prepped for shipment by threading in a bolt and grabbing hold with some pliers twisted and tweaked the bolt. The boss was solid. That made me feel good.

The solution is a simple, easy install rivet nuts in place of the brazed-in boss that came out. The photos below show that process. Takes a few minutes

That’s it. I thought about not putting this out there because that’s what companies do – hide things and then act surprised when something happens. But, I owe this to all the folks who have put their trust in my frames and I thank each of you for that.

One final bit, this is limited to the second run of cross frames only.

And to make this long post even longer, here is the process to install rivet nuts.

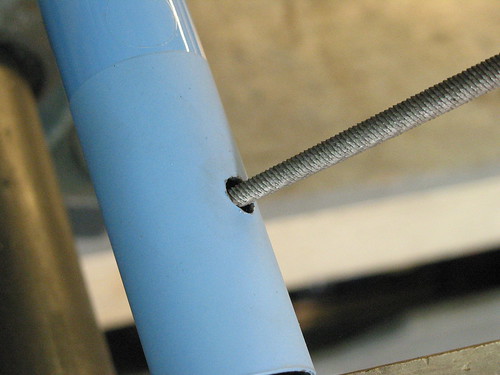

The hole for a brazed in bottle boss is smaller than the rivet nut outer diameter of about 7mm.

So the hole will have to be made larger. You can use a tapered reamer like pictured here. Or if you have enough space within the frames front triangle, you can drill the hole larger. Just be careful not to go too far into the tube that you punch into the other side of the tube.

A file can also be used to open the hole for the rivet nut insertion.

Verify the rivet nut fits snugly in the hole.

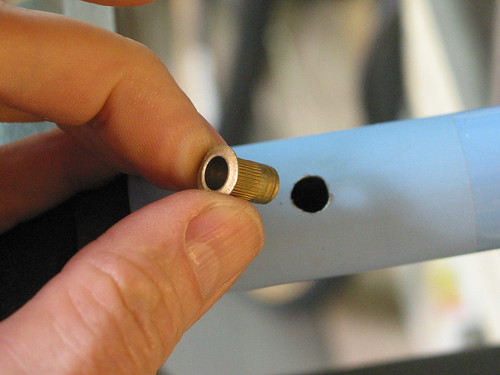

The rivet nut installation tool with a rivet nut.

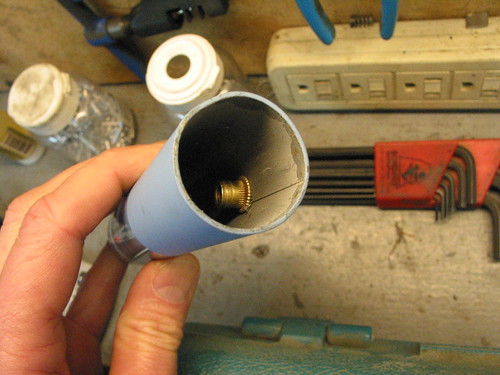

Thread the rivet nut onto the tool’s mandrell so all threads are engaged.

Back the mandrel up so the flange of the rivet nut is flush against the tool’s stop.

Fit the rivet nut firmly against tube and…

…squeeze the tool’s plier handles.

When installed, the rivet nut is compressed up to the inside of the tube creating a sandwich with the frame tube.

(What’s playing: Bob Dylay & The Band Too Much of Nothing)

Well done. Customer satisfaction is guaranteed. Cherry on top it the rivnut pro tip.

Those "other" companies that would hide these things are watching and hopefully learning, or they will be fading into the background

For what it's worth, you can build your own rivet nut tool with about 25 cents worth of fasteners from any hardware store. I used a ~1" M5 bolt, an M5 nut, and a washer. If you only have to do the job once or twice, it saves you ~$50. And you can buy a pack of 25 rivet nuts from McMaster Carr for ~$10. P/N 94020A375

Great job on the customer service though. It's rare (and greatly appreciated) these days.

Totally the right thing to be open about this. I'm not in the market for another bike, but if I was, this post would have made me even more confident about buying one of yours.

I commend you for being open about this and offering some excellent (and generous) solutions.

There's nothing wrong with riv-nutted bottle bosses. Some custom frames that cost thousands use riv-nut bosses and they stay strong for years. The upside is they can be replaced easily in the event of cross threading.

Oh man, you fools, water bottles are for dinosaurs. Hydrations packs and sippy straws are what is up.

And disc brakes.

Hey, Mike, have you initiated dialog with the frame manufacturer with specific reference to the issue?

If so, it'd be interesting to hear about any resolution that is reached.

Discs…

I'm going to assume you be joshin

There's nothing wrong with rivnuts period. Four of them held a strut tower brace in a friend's VW GTI with no issues. If any frames are returned I would have no qualms riding one.

This is really great service. The same thing happened to me on my 2008 Cannondale SuperSix (made in USA eh?) and C'dale couldn't have cared less. I finally resorted to JB weld and it's stayed put ever since. This is a much nicer solution and refreshing that you stand behind your product. Well done sir.

I'm currently in the middle of a Salsa Fargo build and I'm taking a lot of inspiration from your blog. I wish I had known about BMC when I lived in the Presidio and was doing weekend rides to coastal Marin.