By blackmountaincycles,

Filed under: Uncategorized

Don’t stick out, or I’ll cut you off. If you’re the threaded end of a quick release skewer, that is. Most complete bikes are supplied with quick releases where the skewer end doesn’t extend past the adjusting nut. However, if you buy an aftermarket set for your bike, chances are that you just bought a set of quick releases with extra-long skewers to fit any situation. On a steel bike frame, dropouts are typically thinner than those that are on aluminum or carbon frames. What to do with that extra 5mm threaded end sticking out? Cut if off, of course!

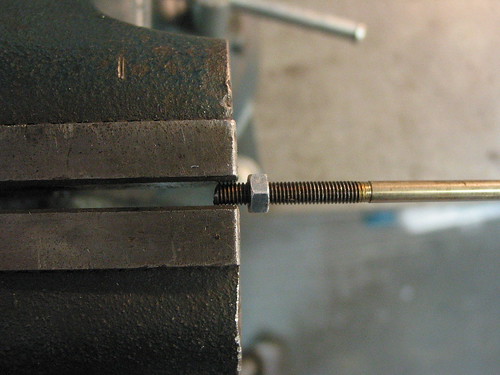

Here’s my trick to cutting down quick release skewers. First, install the quick release and tighten to the frame or fork. Measure the amount sticking out. Thread a 5mm nut onto the skewer end stopping at the point you want to cut. Clamp in a vice and cut off the end of the skewer with a hacksaw. The nut is now still threaded on to the skewer. Spin the nut further down and file the rough cut end or spin it on a grinder wheel. Now that nut you threaded on earlier becomes a die of sorts as you remove it, it further cleans up the thread end. Finally, reinstall it all and clamp to an appropriate tension.

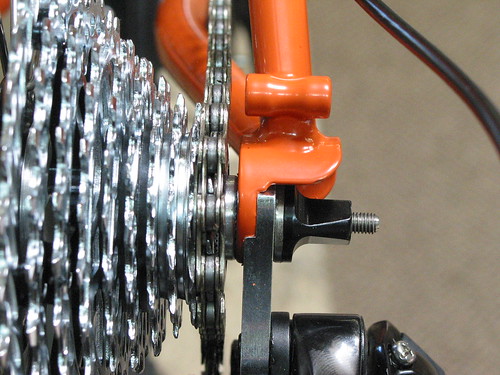

Before

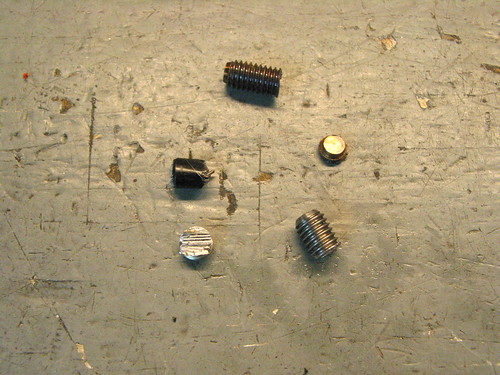

After

Cut

Didn’t make the cut. That piece of shift housing is there because the length I cut between two stops was just that much too long.

(What’s playing: KWMR Release Me)

« Prev

Differences…

Differences…

Next »

Not a real bike shop…

Not a real bike shop…

Thanks for the reminder. I need to trim the rear Pitlock skewer since it comes for a 135mm rear end.

Nice. I need to inspect my QRs!

do you keep the protective shipping film on you phil hubs, mini fridge, tv, etc? I do, it drives my buddies nuts, which is always good!